Yongjin - high production reeling cotton gauze roll or medical gauze bandage looming making machine YJ-V 8/27

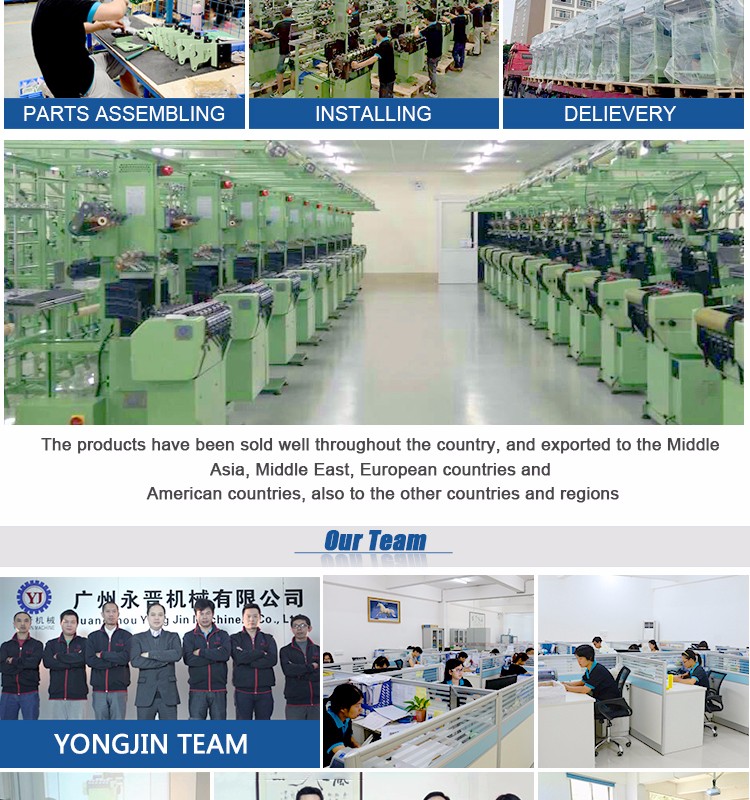

In this era, it is necessary for any enterprise including Guangzhou Yongjin Machinery Co., Ltd. to improve our R&D strength and develop new products on a regular basis. high production reeling cotton gauze roll or medical gauze bandage looming making machine attaches great importance to technological innovation in the research and development process. We strictly stick to the concept of scientific design, which contributes to the unique appearance and easy-to-use performance of our weaving machine, jacquard loom, needle loom. Also, we never use inferior raw materials and ensure they are all tested by our QC inspectors, thereby, guaranteeing Weaving Machines quality. We believe that our product with so many advantages can bring benefits to all customers.

| Applicable Industries: | Manufacturing Plant, Textile Industry | Showroom Location: | Turkey, Viet Nam, Indonesia, Thailand, Bangladesh |

| Condition: | New, New | Type: | Shuttle Loom |

| Application: | To produce narrow fabric, It can be used To produce jacquard elastic and non-elastic webbing | Production Capacity: | The maximum machine speed:1700, 300sets / month |

| Place of Origin: | Guangdong, China | Brand Name: | YongJin, YongJin |

| Dimension(L*W*H): | 1.5m*0.98m*2.1m, 1.5*0.98*2.1m | Weight: | 400kg |

| Power: | 1.1KW | Warranty: | 1 Year |

| Key Selling Points: | Automatic | After Warranty Service: | Video technical support, Online support |

| Local Service Location: | Turkey, Thailand | After-sales Service Provided: | Video technical support, Online support, Engineers available to service machinery overseas |

| Certification: | ISO9001,3C | Commodity name: | leno fabric gauze korouche looming weaving machine |

| Model Number: | YJ-V8/27 | Place of origin: | GuangZhou, China |

| Export Markets: | Southeast Asia, the Middle East, Europe and America |

high production reeling cotton gauze roll or medical gauze bandage looming making machine

We are manufacturer (Quality Guaranteed , Integrity Services, Competitive price )

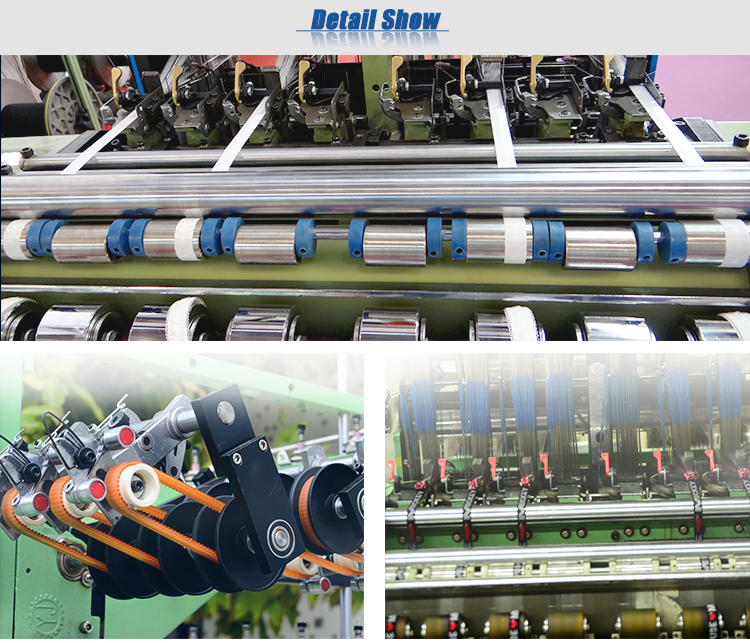

This is the shuttle less loom , this machine is to produce elastic belts, etc., the structure is same as Muller's, over 95% of spare parts can interchange with Muller.

Besides, we installed the inverter system, can control the speed easily stop the machine immediately, also protect the yarn.

We also upgrade the structure of machine, in order to improve the speed, to compare with other brand, the output is 15% higher than others.

Video link

https://youtu.be/80VmuYpsSWg

| Model | 2/110 | 4/65 | 6/50 | 8/30 | 12/15 | 8/30-2 | 12/18-2 |

| Length of frame | 550MM | ||||||

Number of tapes | 2 | 4 | 6 | 8 | 12 | 16 | 24 |

| Width of reed | 110 | 65 | 50 | 30 | 15 | 30 | 18 |

| Maximum of tapes | 100 | 63 | 48 | 28 | 13 | 28 | 16 |

| Number of frame | 16 | 16 | 16 | 16 | 16 | 16 | 16 |

| Power/Voltage | 1.1KW/380V | ||||||

| Circulation | 1:8/16-48 | ||||||

| Speed | 800-1500rpm | ||||||

| Main Features |

1.It is small in size and good-looking in appearance. |

2.The principal axis is electromagnetic braking. It is easy-to-use and sensitive to start and stop, and not cause to any useless tapes. |

3.The single iron frame being divided on two sides and oriented in the middle, it can change to various flower shape and different kinds of tapes. |

4.It is featured by double weft and double hook and can weave every complex ribbon and double Z-type ribbon. |

5.The advanced automatic weft feeding device ensures fine tuning of weft feeding when non-stop of machine. |

6.The cam is characterized by its novel profile, no making too much noise and its high-quality lockrand. |

7.The number of lines of strips can be changed quickly and efficiently.Motor power is 1.1KW |

8.The coiling setting is small in size and easy-to-use, and the coiling tape setting will stop automatically. |

CONTACT US

If you have more questions, write to us. We sincerely hope to cooperate with friends from all walks of life, work together to create a better future!