China Automatic Sampling Warping machine manufacturers-Yongjin

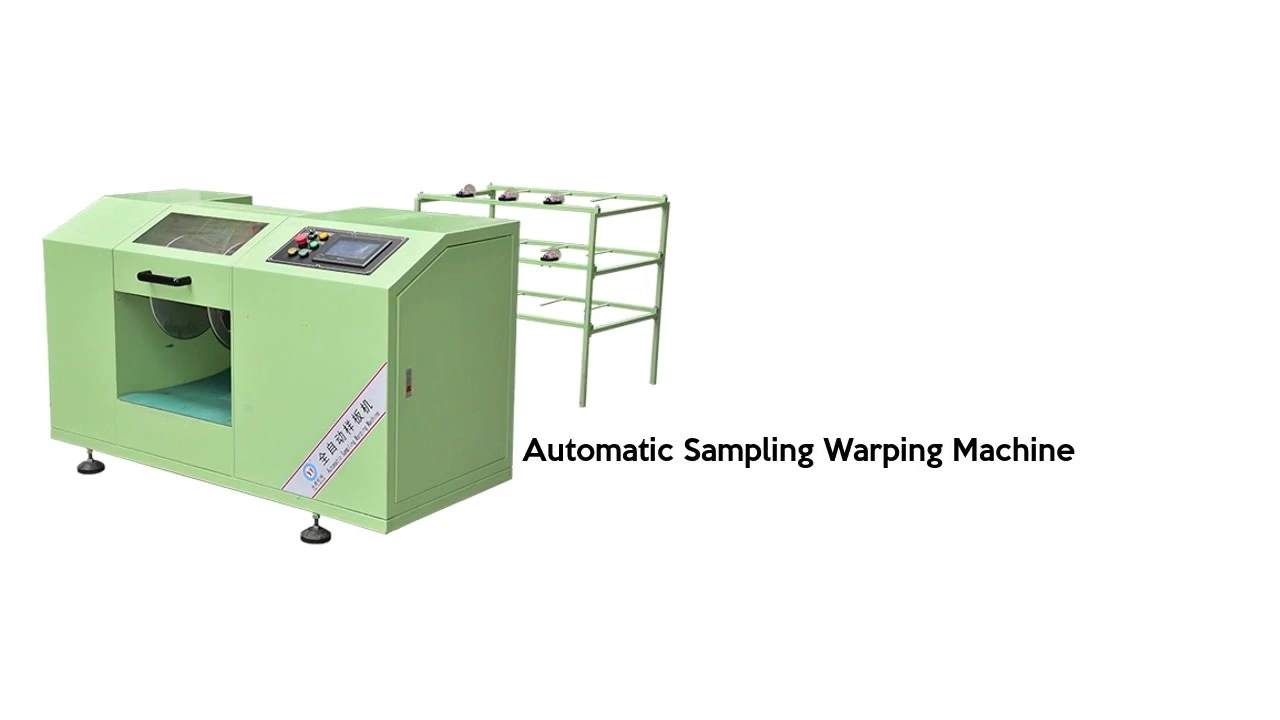

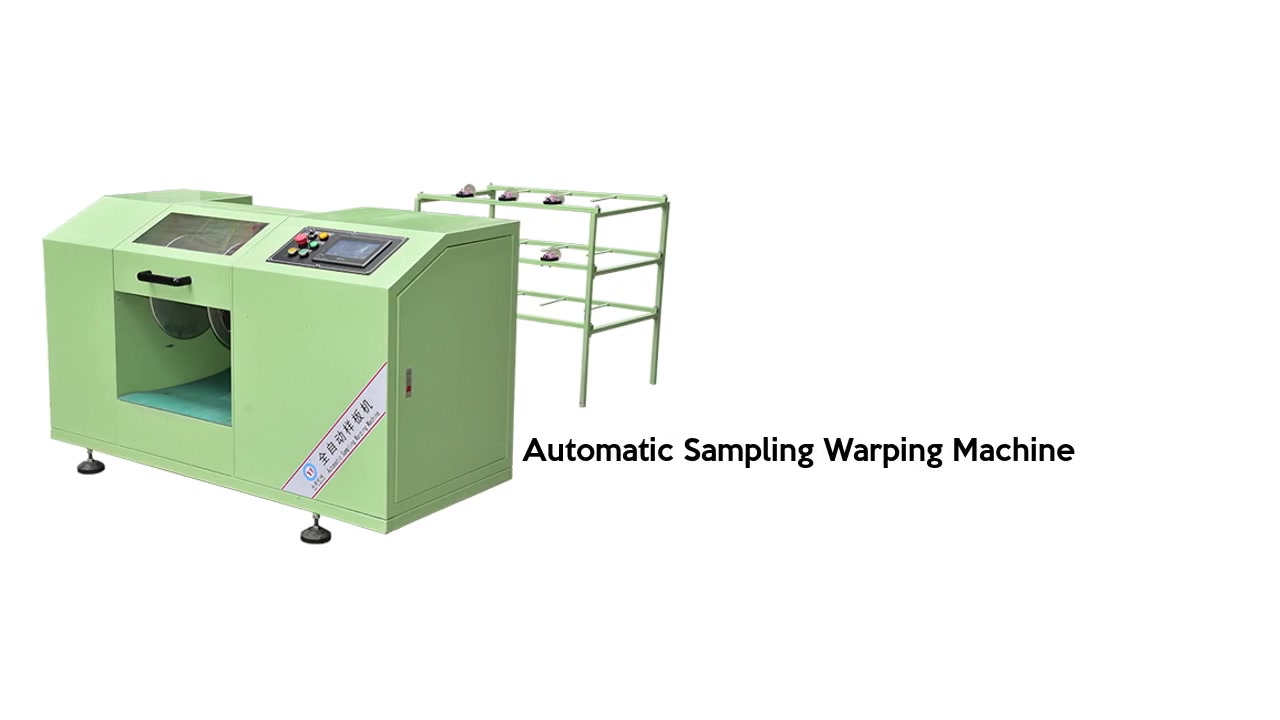

Automatic Sampling Warping Machine.

The sample warper uses a new concept of warping method. It can use one or several raw yarn or sizing bobbin yarns to process the weaving axis,

greatly reducing the amount of warping and simplifying the work process. Reduced sample time and production costs.

The sample warper uses a new concept of warping method. It can use one or several raw yarn or sizing bobbin yarns to process the weaving axis, greatly reducing the amount of warping and simplifying the work process. Reduced sample time and production costs.

The machined weaving shaft is used for the trial weaving sample on a wide-format shuttleless or shuttle loom, so the sample fabric obtained by weaving and finishing is very close to the product in mass production in terms of style and performance. When warping, the length of the winding of the bearing is 7 m or 7 m.

At present, the maximum length of the yarn is up to 420m. Due to the simplification of the original processing process with large yarn consumption, long process flow and slow response speed, the device is a powerful tool for new product development and fabric sample knitting.

CONTACT US

If you have more questions, write to us. We sincerely hope to cooperate with friends from all walks of life, work together to create a better future!